Looking back at my journey, it’s clear to me that leadership, expertise, and growth aren’t formed in a single moment of brilliance—they’re the result of years of consistent effort and learning. My career started 30 years ago, and it’s been a journey of continuous improvement—focused on the idea of improving just 1% each day.

Looking back, my journey began humbly as a Warehouse Associate at Honda Cars, with even a brief hands-on stint on the production line. It was early in my career when I was first exposed to the principles of continuous improvement through Quality Circles. Participation was voluntary and unpaid, taking place after working hours. Some advised me against it, saying it was a waste of time, but I saw it as an opportunity to grow.

That dedication culminated in our participation in a Quality Circle competition with the project, “Process Simplification Through Streamlining of Parts Handling Operations.” At the time, I didn’t even know what “LEAN” was, yet unknowingly, we were applying its very principles. Although we didn’t win—facing off against the very experts who had taught us—the experience was far from a loss. It taught me that success isn’t only measured by trophies but by the mindset you develop along the way. It shaped my understanding of the power of teamwork, the value of persistence, and the importance of continuously challenging the status quo.

It was also during this period that I first learned to conduct Time and Motion Studies to establish Takt Time—a skill that would later become fundamental in my leadership journey toward Operational Excellence. That early experience planted the seeds of a leadership philosophy I still carry today: always invest in learning, embrace challenges, and lead by example, no matter the circumstances.

When I stepped into the role of Quality Assurance (QA) Engineer at Integrated Microelectronics Inc. (IMI), I took the lead on a “Customer Lot Acceptance Rate Improvement Project.” Through relentless effort and process refinements, we were able to raise the acceptance rate from 80% to 97%. It wasn’t an overnight success—far from it. It was the result of consistent, incremental improvements. That experience taught me a powerful lesson: real, lasting growth is built day by day. It’s the small, continuous actions—the essence of Kaizen—that eventually lead to significant transformation.

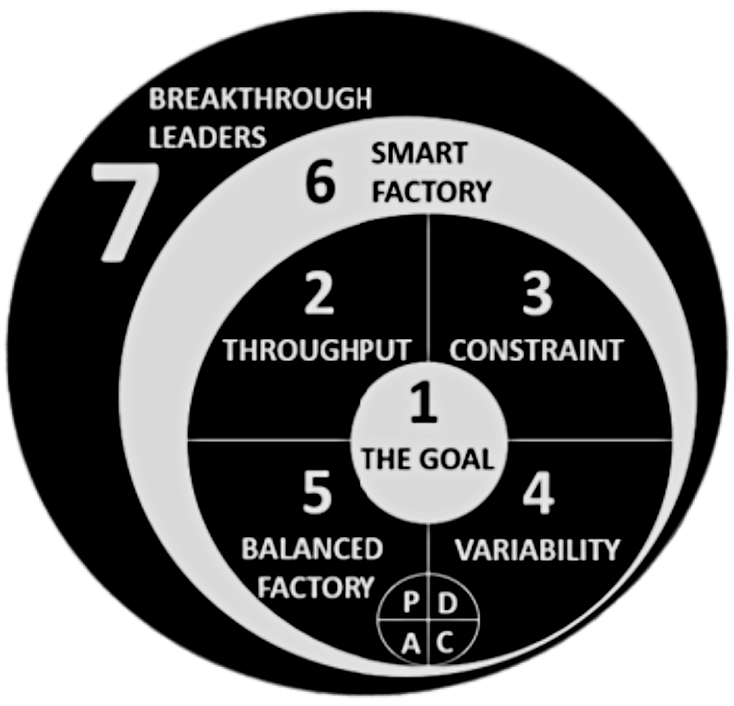

Later, when I transitioned to Intel in Cavite as a Manufacturing Supervisor, I was introduced to the Theory of Constraints. It made me rethink fundamental questions, like What is the right level of inventory? I challenged conventional thinking and developed my own formula that engineers could practically apply. This curiosity led me to explore Factory Physics and Little’s Law, both of which profoundly shaped my understanding of operations management.

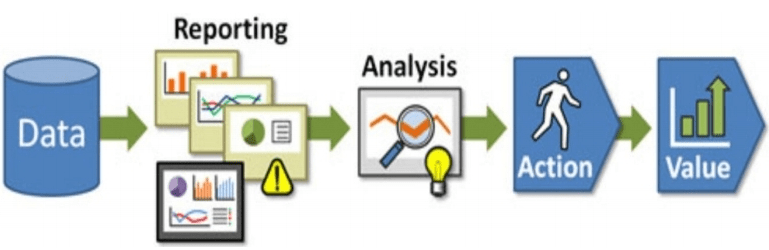

My journey at Intel continued to unfold as I earned a promotion to Manufacturing Integration Manager—a defining chapter, as I share in The Leadership Moment. In this role, I experienced firsthand the true power of Data Automation. We developed our first integrated dashboard, bringing together multiple reports to enable faster, more informed decision-making. The results were immediate and eye-opening. That experience ignited in me a lasting appreciation for the transformative impact of data-driven leadership and how it can elevate operational excellence to new heights.

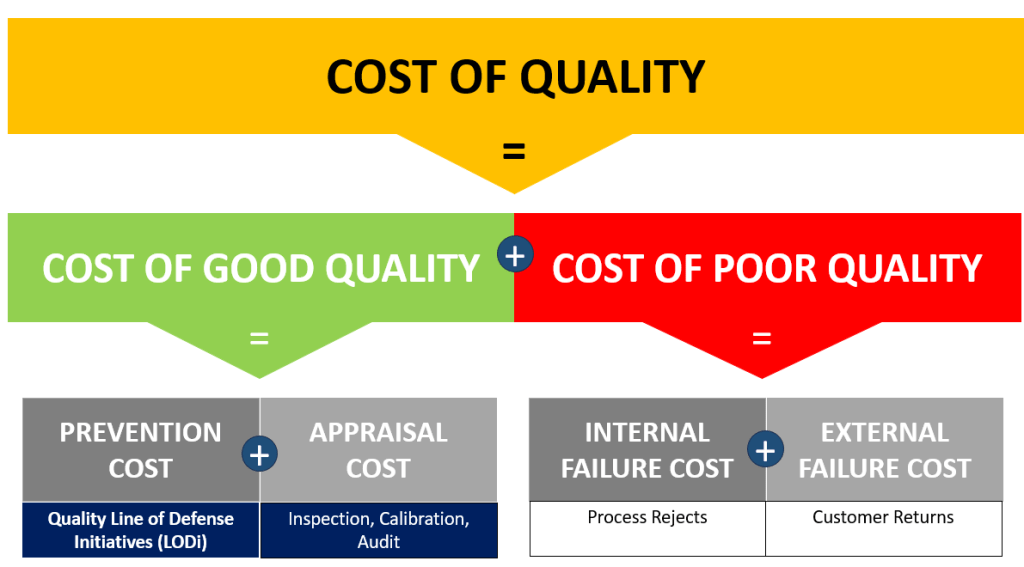

That experience stayed with me, and when I moved to Malaysia with Jord International as Planning Manager, I championed the development of a similar dashboard to streamline operations, which also allowed us to refine our Standard Cost framework. Later, in China with Micron Semiconductor, I continued this journey by advocating for an advanced tool that not only improved decision-making but also enhanced our Dispatching (What’s Next) and Scheduling (Conversion Plan) processes that directly involve the one doing the actual execution in Production line. Today, I take pride in seeing how what began as a simple tool back in Cavite has evolved into its fourth iteration, now transforming how we manage data, material releases, and operational flow on a much larger scale. My time in China also deepened my understanding of quality management, as I was introduced to concepts like the Cost of Quality and the Quality Line of Defense—both of which have strongly shaped my proactive approach to driving quality across the organization.

But my journey didn’t end there. During this time, I encountered The Goal by Eliyahu Goldratt, a book that profoundly shaped my thinking. It crystallized a simple yet powerful truth: the core purpose of any business is to make money—but more importantly, to pursue continuous growth. This insight became the cornerstone of the 7 Fundamental Principles I follow today, with Principle #1 — The Goal — affirming that a business exists not only to generate profit but to sustain and drive ongoing growth.

Over time, my experiences across Honda Cars, IMI, Intel, Jord International, Micron Semiconductor, and Coherent came together to shape my leadership and operational philosophy. The tools and principles I picked up along the way—from data automation to capacity planning—deepened my understanding of what truly drives success. It was through these roles that I fully embraced the power of continuous improvement.

When I returned to the Philippines to join Coherent, first as Plant Manager and later as Country Manager, I saw the opportunity to bring all those lessons to life. In this role, I added a vital dimension: Finance. It felt like the culmination of everything I had built in data automation throughout my career. At Coherent, I gained access not only to production metrics but also to Expenses, CAPEX, and Budget management—the financial levers that truly propel the business forward. This broader perspective empowered me to manage resources more effectively, safeguard profitability, and achieve the business goals that have always guided my journey.

I wanted to share this holistic mindset with my team, so I laid out my vision: “Let’s aim to be 1% better than we were yesterday, every single day. Let’s pursue personal growth—not for anyone else, but for ourselves.”

Leadership, much like operations management, is a continuous journey. It’s about showing up, embracing challenges, and making small, consistent improvements—not just for the organization, but for our own growth. Each of us holds the power to make incremental changes that, over time, compound into meaningful transformation. These small steps shape us into stronger leaders, sharper professionals, and better individuals.

Now, imagine where you could be a year from today if you commit to daily growth, even in the smallest of ways. Every action, no matter how minor, moves you closer to the person you aspire to become. The future is built in the present—so start today.

If you reached this point, without skipping a word, then you understood the Law of the Process.