In the modern manufacturing landscape, technology is not just about automation—it’s about enabling excellence. A Smart Factory integrates advanced automation, real-time data, and connected systems to optimize operations, but its true value lies in how it empowers employees to make better, faster, and more informed decisions. By eliminating inefficiencies and providing instant access to critical insights, a Smart Factory enhances both operational performance and employee engagement.

Key Advantages of a Smart Factory

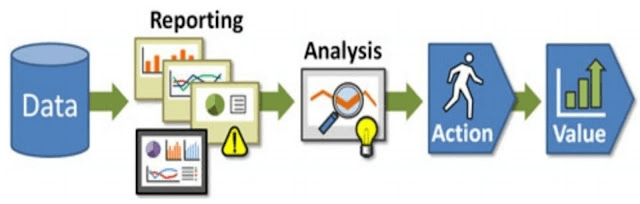

🔹 Data-Driven Decision-Making

With real-time dashboards, employees no longer need to spend hours manually compiling reports. Instead, they have instant access to critical production metrics, enabling them to make timely and well-informed decisions that drive operational efficiency and business success.

🔹 Enhanced Productivity and Efficiency

By automating repetitive and time-consuming tasks, a Smart Factory allows employees to focus on high-value activities such as problem-solving, process optimization, and continuous improvement. This shift from manual labor to strategic work increases engagement, motivation, and job satisfaction.

🔹 Predictive Maintenance and Proactive Problem-Solving

With real-time monitoring and AI-driven analytics, potential equipment failures can be detected before they cause downtime. Instead of reacting to breakdowns, employees can take a proactive approach, ensuring smooth operations and uninterrupted productivity.

🔹 Optimized Inventory and Supply Chain Management

Smart Factories provide real-time visibility into inventory levels, reducing waste, preventing shortages, and improving supply chain responsiveness. Employees can make data-backed decisions to streamline production schedules, ensuring the right materials are available when needed.

🔹 Improved Quality and Yield

Automation enhances quality control by detecting defects in real time, allowing for immediate corrective action. Employees no longer have to manually inspect every unit, freeing them to focus on continuous quality improvements and innovation.

🔹 Empowered Workforce and Continuous Improvement

Technology in a Smart Factory does not replace employees—it elevates their role. With easy access to insights, employees are more engaged, more capable, and more empowered to drive efficiency, quality, and innovation. A culture of data-driven problem-solving leads to sustained operational excellence.

The Future of Manufacturing: People and Technology Working Together

A Smart Factory is not just about automation—it’s about creating an environment where people and technology work hand in hand to drive excellence. When employees are empowered with real-time insights and freed from mundane tasks, they contribute more strategically, innovate more effectively, and lead the way in operational success.

Companies that embrace this transformation will not only increase productivity and profitability but also build a highly engaged and future-ready workforce. The question is no longer if you should adopt Smart Factory principles—it’s how fast you can make the shift.

Are you ready to take your operations to the next level? The future belongs to those who act today. 🚀