In operations, variability reduces the predictability of the constraint, making it difficult to maximize throughput and achieve consistent performance. Uncontrolled variability leads to missed commitments, inefficiencies, and increased costs.

Principle #4: Variability. Variability dictates the predictability of the constraint.

To maintain a stable and predictable operation, we need a strong defense strategy that identifies and eliminates variability before it impacts the constraint.

🔥 The Four Lines of Defense Against Variability

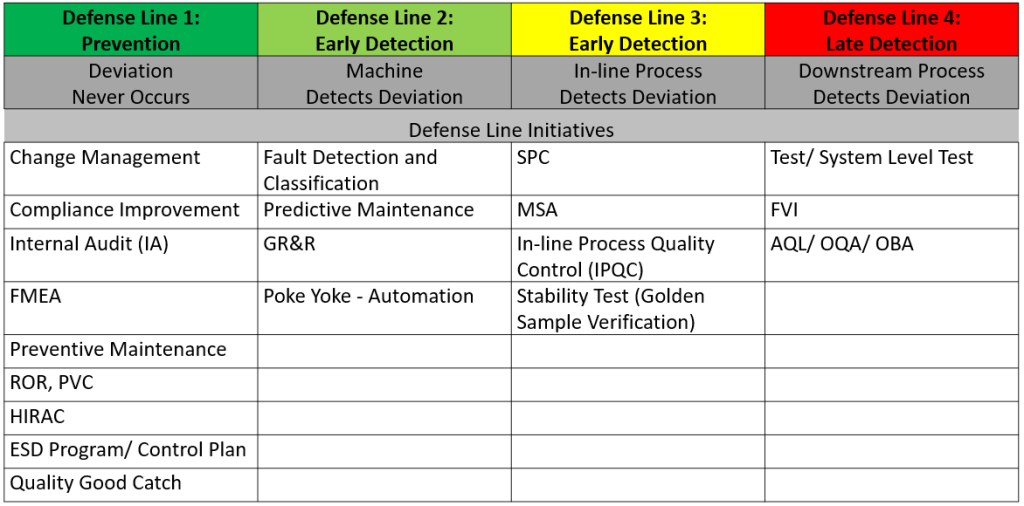

One systematic way to reduce variability is through the Quality Line Of Defense Initiatives. It systematically looks into system weaknesses. This starts with the very obvious, which is visual, and then addresses the system of controls or preventative controls. We call this approach Shift Left Strategy. It involves moving quality improvements further up the value chain. The goal is to prevent problems as early as possible across all departments in the enterprise. This helps in minimizing risk and cost to the company.

Quality Line of Defense Initiative (LODi) is a systematic and collective way to ensure that the quality of our products meets customers’ expectations. We should all agree that preventive and early detection are better than late detection. These involves inline compliance and real-time monitoring to meet the quality expectations of our customers. Through this effort, process variability can be reduced.

🏆 Defense Line 1: Prevention – Deviation Never Occurs

- Standardize processes and eliminate variability at the source

- Implement high-quality materials and controlled inputs

- Enforce best practices and automation to reduce human error

🏆 Defense Line 2: Early Detection – Machine Detects Deviation

- Utilize predictive maintenance and sensors for real-time anomaly detection

- Set automated alarms and shut-off mechanisms before issues escalate

- Ensure machines self-adjust to maintain process stability

🏆 Defense Line 3: Early Detection – Inline Process Control Detects Deviation

- Deploy real-time monitoring in production lines

- Implement Statistical Process Control (SPC) and AI-driven analytics

- Use inline quality checks to correct deviations before they reach the next step

🏆 Defense Line 4: Late Detection – Downstream Process Detects Deviation

- Final quality control and end-of-line inspection

- Implement rework and recovery plans to minimize losses

- Conduct root cause analysis to prevent recurrence

🎯 Why This Matters?

A predictable constraint is a productive constraint. The stronger the Four Lines of Defense, the better we can control variability, improve efficiency, and protect throughput.

📌 How does your company manage variability? Let’s discuss!

#OperationsManagement #Variability #DefenseLineStrategy #ContinuousImprovement #ManufacturingExcellence #Throughput #Engaged