Principles are constant, observable, and logical. They offer coherence, comprehension, and consistency—providing a foundation for decision-making and guiding organizations in the right direction. These principles endure the test of time, shaping the way businesses operate and thrive.

This is a culmination of decades of experience in manufacturing, supply chain, and operations management, blended with insights from literature and industry best practices. Since the Industrial Revolution, businesses have continuously evolved, yet the core principles that drive Operational Excellence remain unchanged.

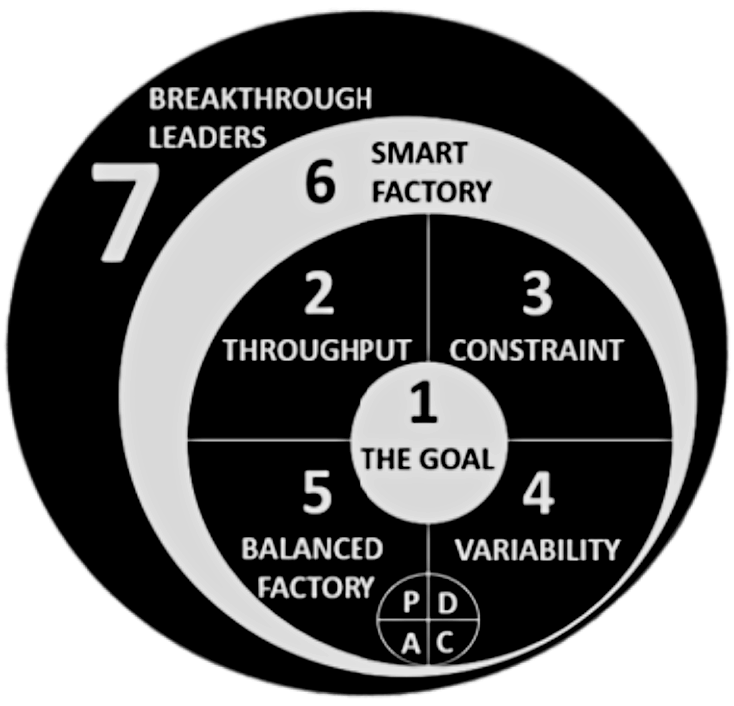

At its heart is the 7 Fundamental Principles in Operations Management—a timeless framework that equips leaders and professionals with the tools to optimize productivity, maximize profitability, and achieve sustainable growth.

By understanding and applying these principles, organizations can:

✅ Align teams towards a common goal

✅ Identify and improve key performance metrics

✅ Streamline processes and remove bottlenecks

✅ Enhance predictability and reduce operational risks

✅ Leverage technology for smart decision-making

✅ Foster a culture of innovation and continuous improvement

Here’s a deep dive into these 7 Fundamental Principles in Operations Management:

🔹 Principle 1: The Goal – “The goal of a business is to make money and continually grow.”

At the core of every successful organization is profitability and sustainable growth. While businesses have different visions and missions, the fundamental purpose remains the same: to generate revenue, improve costs, and reinvest for future expansion.

This principle shifts the focus from merely cutting costs or increasing production to understanding the real driver of business success—throughput. When organizations recognize that true success comes from maximizing revenue while ensuring long-term stability, they can make informed decisions that impact their bottom line.

🔹 Principle 2: Throughput – “Throughput is the rate at which the business generates money through sales.”

Throughput measures the speed at which an organization turns inputs into revenue. It’s not enough to produce more; what truly matters is selling what is produced at the right time and in the right quantity.

By optimizing throughput, businesses:

📈 Improve cash flow and working capital

📈 Reduce excess inventory and waste

📈 Align production with real customer demand

📈 Enhance overall profitability

The key takeaway? Revenue isn’t just about volume—it’s about velocity.

🔹 Principle 3: Constraint – “Constraint dictates throughput performance.”

Every system has a bottleneck—a limiting factor that dictates how much can be produced or delivered. In manufacturing, this could be machine capacity, raw material availability, or labor efficiency. In service industries, it could be response time, skill gaps, or approval processes.

To achieve Operational Excellence, companies must:

🔍 Identify constraints

🔍 Optimize and alleviate bottlenecks

🔍 Ensure resources are directed where they matter most

By focusing on constraints rather than spreading efforts thin, organizations can drastically increase productivity and throughput.

🔹 Principle 4: Variability – “Variability reduces the predictability of the constraint.”

Variability introduces uncertainty in processes, making it difficult to keep a steady and predictable output. Whether it’s fluctuations in customer demand, supply chain disruptions, or machine downtime, uncontrolled variability undermines efficiency.

Managing variability requires:

🔹 Standardization of processes

🔹 Real-time monitoring and predictive analytics

🔹 Flexibility in production and supply chain strategies

By reducing variability, businesses can improve forecasting accuracy, keep steady throughput, and enhance operational reliability.

🔹 Principle 5: Balance Factory – “A balanced flow system protects the system from variability.”

A well-balanced factory ensures that resources flow efficiently without delays or excess capacity. Unlike traditional production models that prioritize maximizing individual machine output, a balanced system optimizes overall flow and synchronization.

Achieving a balanced factory involves:

✅ Workload leveling across production stages

✅ Minimizing work-in-progress (WIP) inventory

✅ Ensuring smooth handoffs between departments

When the system is harmonized, productivity increases, costs decrease, and businesses become more agile in responding to customer demands.

🔹 Principle 6: Smart Factory – “Technology is an enabler towards excellence.”

The rise of Industry 4.0 has revolutionized operations. Technology is no longer just an add-on—it’s a critical enabler of business success. Smart factories leverage automation, AI, IoT, and data analytics to enhance productivity, efficiency, and decision-making.

Embracing the Smart Factory means:

🤖 Automating repetitive tasks to reduce errors and increase speed

📊 Using real-time data analytics to make informed decisions

🌍 Implementing connected systems to improve supply chain visibility

A business that fails to adopt smart technologies risks falling behind. Those that do gain a competitive edge.

🔹 Principle 7: Breakthrough Leaders – “Leaders make things happen.”

Great operations don’t just run on processes and systems—they run on people. Strong leadership is the key to driving change, fostering innovation, and ensuring long-term success.

Breakthrough leaders:

🚀 Set clear goals and inspire teams

🚀 Encourage continuous learning and improvement

🚀 Make data-driven decisions and take calculated risks

🚀 Create a culture of accountability and ownership

Operations excellence starts at the top. The best leaders don’t just manage—they empower, transform, and elevate their teams.

📌 The Path to Operational Excellence

These 7 Fundamental Principles in Operations Management are more than just concepts—they are actionable strategies that drive real results. Whether you’re leading a manufacturing plant, a semiconductor operation, or a service business, these principles provide the roadmap to greater efficiency, profitability, and sustained growth.

These principles are not just added knowledge —it’s about transformation. The insights within these pages will equip you with the tools to navigate the challenges of modern operations and build a future-proof organization.

Are you ready to take your operations to the next level? Join us in exploring, implementing, and mastering these principles—the foundation of true Operational Excellence.